|

|

|

| |

|

|

|

|

|

|

- (1)

- (1)

- (1)

- (2)

- (1)

- (2)

- (1)

- (1)

- (1)

|

|

| |

|

|

Build Your Online Product Catalogs?

| Product Name: |

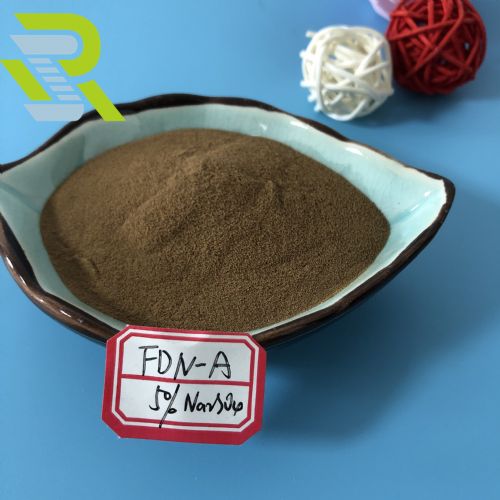

Naphthalene Superplasticizer for Concrete Admixtur

|

| Supply Ability: |

|

| Related proudcts |

concrete admixture, snf, fdn, |

| Specifications |

FDN A 5%, FDN AI 10%, FDN AII 18%. |

| Price Term: |

FOB CIF |

| Port of loading: |

Qingdao |

| Minimum Order |

6 |

| Unit Price: |

600-1200 |

|

Naphthalene superplasticizer

Chemical name:

¦Â Sodium naphthyl sulfonate formaldehyde condensate. Molecular formula:

(c10h6ch2naso3) n, n is mainly 9-12. Naphthalene superplasticizer has good adaptability to various cements and improves

the operability of concrete.FDN has the advantage of high water reducing ratio, non-delayed

coagulation, non-air entraining and strong adaptability. It can improve the workability of

concrete to a large extent so as to reduce the water consumption for blending. Meanwhile, it

can improve the strength of concrete.

It is widely used in concrete engineering: highway, railway, bridge, tunnel, power station, dam, high-rise building and other projects.It has good dispersion, water reduction and

early-strength effect.Adding naphthalene series superplasticizer into ordinary concrete can

improve the physical and chemical properties of concrete, improve the concrete strength, construction speed, project quality, technology and working conditions. 1. early strength admixture - improve construction progress;

2. retarding admixture - prevent cracking of large infrastructure such as airports and bridges;

3. pumping type admixture - transported by pump, such as high-rise buildings;

4. antifreeze admixture - used for winter construction. FDN-A High concentration product with sodium sulfate content no more than 5 percent. FDN-AI Middle concentration product with sodium sulfate content no more than 10 percent. FDN-AII Low concentration product with sodium sulfate content no more than 18 percent. FDN-23 sodium sulfate content no more than 23 percent,cheapest type to save cost. Usage method:

--Powder 0.5%-1.0%, recommended dosage 0.75%; --Liquid is 1.0%-2.0%, and the recommended mixing amount is 1.5%. The mixing amount

can be appropriately increased according to the grade of concrete. --Each batch of goods must be tested to meet the engineering requirements before use. 1. As the requirement of engineer,the dosage can be adjusted after testing. 2. It can be put into blender with mixing w |

| Company: |

ZIBO JOYREACH NEW MATERIALS CO.,LTD

|

| Contact: |

Ms. Harriet Gu |

| Address: |

Zhangdian District,Liuquan Road 296, |

| Postcode: |

255000 |

| Tel: |

86-13964318618 |

| Fax: |

0533-2341662 |

| E-mail: |

|

|

|